Rheology Testing

NETZSCH manufactures an array of rheometers for Research, Product Development, and Quality Control. A rheometer is a device used to measure the rheological properties of materials which describes the interrelation between force, deformation and time.

Besides, we represent JSR Corporation to supply CURELASTOMETER® (reg. TM of JSR Corporation) & Moving Die Rheometer (MDR). CURELASTOMETER® became the world’s first curemeter to feature a rotorless design, now is the most popular form of curemeters used by the industry. There are two models available: Type R for rubber and Type P for resin. Curemeter Type R conforms with JISK6300-2 and ISO6502.

CURELASTOMETER® enables any operator to safely and easily acquire comprehensive data on curing/hardening rate and other behavioral properties to the processing of rubber and thermosetting resin, all in one shot with just a small sample. It is mainly used as a testing instrument in R&D, processability testing, and production line quality control.

Showing all 9 results

-

Curemeter CURELASTOMETER® TYPE R 7 For Rubber

-

Kinexus DSR-III Rheometer

-

Kinexus Lab+ Rheometer

-

Kinexus Pro+ Rheometer

-

Kinexus Ultra+ Rheometer

-

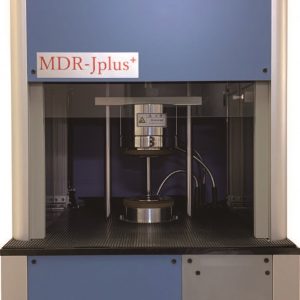

Moving Die Rheometer (MDR-Jplus+)

-

Resin Hardening Instrument – CURELASTOMETER® TYPE P

-

Rosand RH2000 Bench Top Capillary Rheometer

-

Rosand RH7/ RH10 Capillary Rheometers