Model 100S Extensometer

A typical application is the testing of polycarbonate, where a high resolution system is required to measure the E modulus (Youngs modulus) and a secondary system is required to measure elongation to the point of break, which typically could be as high as 200% strain.

Other materials the 100S extensometer is ideally suited to include polyurethane, polyethylene (PET), glass reinforced plastics (GRP), and aluminum alloys.

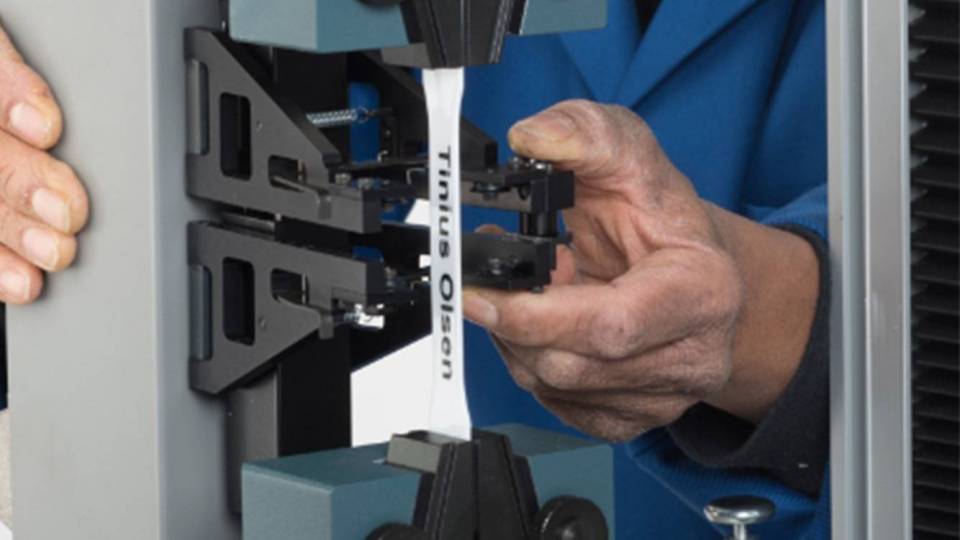

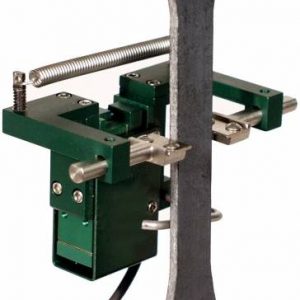

The unique design ensures an extremely low tracking force for testing sensitive materials and a construction that is sufficiently robust to withstand the release force when the specimen breaks. An important feature is an ease with which the extensometer clamps can be attached to the specimen, resulting in very rapid testing throughput.

Measuring Extension

The extension is measured by attaching two counterbalanced extensometer clamps to the specimen at a preselected gauge length.

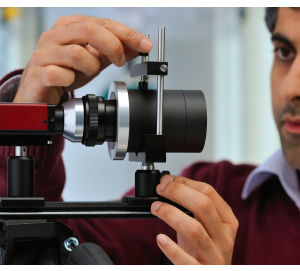

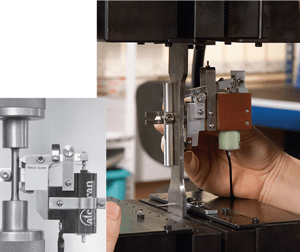

When tensile forces are applied to the specimen by the testing machine, the slightest change in gauge length is measured by a precise LVDT transducer. If the range of this LVDT transducer is exceeded, measurement of elongation and strain transfers to an optical encoder.

Signals from the LVDT and optical encoder are fed into the signal conditioner interface for processing. The 100S extensometer can be fitted to all twin-screw materials testing machines and must be used under software control