Derivatization

It is an inherent advantage of TLC/HPTLC that all analytes remain stored on the plate and can be readily derivatized after chromatography. Analytes that do not respond to visible or UV light can be rendered detectable. In many cases, analytes or classes of analytes can be identified by specific reagents, enabling their selective detection.

Pre-chromatographic derivatization is possible by over spraying the sample application zones with the CAMAG® Linomat 5 , the CAMAG® Automatic TLC Sampler 4 (ATS 4) or CAMAG® HPTLC PRO Module APPLICATION

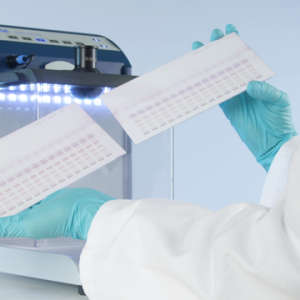

For the transfer of liquid reagents for post chromatographic derivatization, one can choose between spraying or dipping. Automated spraying ( CAMAG® HPTLC PRO Module DERIVATIZATION, CAMAG® Derivatizer ) or manual dipping ( CAMAG® Chromatogram Immersion Device 3) are the preferred techniques, particularly when a quantitative evaluation is intended.

In most cases, the derivatization reaction needs to be completed by heat treatment. Heating the plate at the desired temperature with a plate heater ( CAMAG® TLC Plate Heater 3) specifically designed for this purpose is highly recommended. A plate heating unit is an integral part of the CAMAG® HPTLC PRO Module DERIVATIZATION

Showing all 6 results