Differential Scanning Calorimeter – DSC 300 Caliris® Supreme & Select

The DSC 300 Caliris® Is the Most Comprehensive, Most Reliable and Versatile DSC for Material Characterization on the Market.

No matter if you are working in research & development, quality control, contract testing or the specification of materials for certain applications, information about a material’s behaviour under changing temperatures and different atmospheres are important.

The DSC 300 Caliris® is in line with all relevant DSC standards, such as ASTM E793, ASTM E967, ASTM E968, ASTM E794, ASTM E1356, DIN 51007, etc.

The Differential Scanning Calorimeter -DSC 300 Caliris® can support material identification, process optimization, Quality control, Phase diagrams, Kinetic analysis and Compatibility.

Typical DSC Results

∙ Melting temperature and enthalpy

∙ Crystallization temperature and enthalpy

∙ Specific heat capacity

∙ Solid-liquid ratio (solid-fat content)

∙ Polymorphism

∙ Solid-solid transitions

∙ Liquid crystal transition

∙ Degree of crystallinity

∙ Curing, degree of cure

∙ Glass transition

∙ Oxidative stability

∙ Aging

∙ Purity

∙ Decomposition onset

Modular Design – Maximum Flexibility

Ever-accelerating new material developments, triggered by fast-moving mobility and technical trends, require continuous adaptability. The new generation of NETZSCH DSCs is based on a modular concept. The DSC 300 Caliris® is the only instrument of its kind with interchangeable and exchangeable sensor-furnace modules. The Supreme version of the DSC 300 Caliris® allows the exchange of modules, to be able to adapt to current and future needs.

The DSC 300 Caliris® Supreme – The Future-Proof Choice

This version offers a choice of currently three modules and can be configured to achieve an unrivaled maximum temperature range of -180°C to 750°C. It is possible to update your device at any time to take advantage of the latest technological developments or to change your application. The choice of the module used remains unrestricted. Just choose between broad temperature range, fast heating rates or high sensitivity as needed.

The DSC 300 Caliris® Select – Tailor Made for Your Application

In the Select version of the DSC 300 Caliris®, there is an initial choice between three currently available modules. The maximum temperature range available in the DSC 300 Caliris® Select is -170°C to 650°C. The Select version allows for the exchange of modules of the same type avoiding instrument downtimes.

Both versions come with integrated color touch display, an LED status bar and can optionally be equipped with an automatic sample changer.

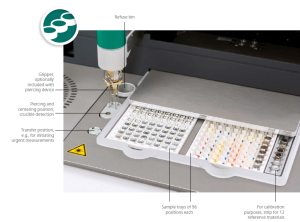

Unique Automatic Sample Changer

Three Modules for Different Needs:

H-Module (HIGH-PERFORMANCE MODULE)

-180°C TO 750°C

The premium module offers the highest sensitivity, accuracy and a very small peak-to-peak noise ratio and impresses with a perfect baseline and outstanding reproducibility – the gold standard for most DSC applications. In combination with the Supreme version, this module covers the entire temperature range from -180°C to 750°C. The H-Module is an ideal complement for advanced materials research and development in both industry and academia.

P-Module (THE POLYMER-MODULE)

-170°C TO 600°C

This module is perfect for all tasks in the polymer field. Its optimized low-mass furnace allows for heating rates of up to 500 K/min over a wide measurement range. Temperature profiles approximating real processing conditions can be realized. Additionally, one can speed up the measurements and thus save valuable time. The P-Module is perfect for research and development or quality control in the polymer processing industry

S-Module (THE STANDARD MODULE)

-170°C TO 600°C

The routine module combines high stability and optimized resolution of thermal effects. Laser-guided welding processes for the sensor disks and thermocouple wires yield true sensitivity and robustness. The monolithic DSC sensor features high metrological stability and optimal resolution. The easy to handle S-module is the module of choice for industry and contract laboratories when routine measurements are the main task.

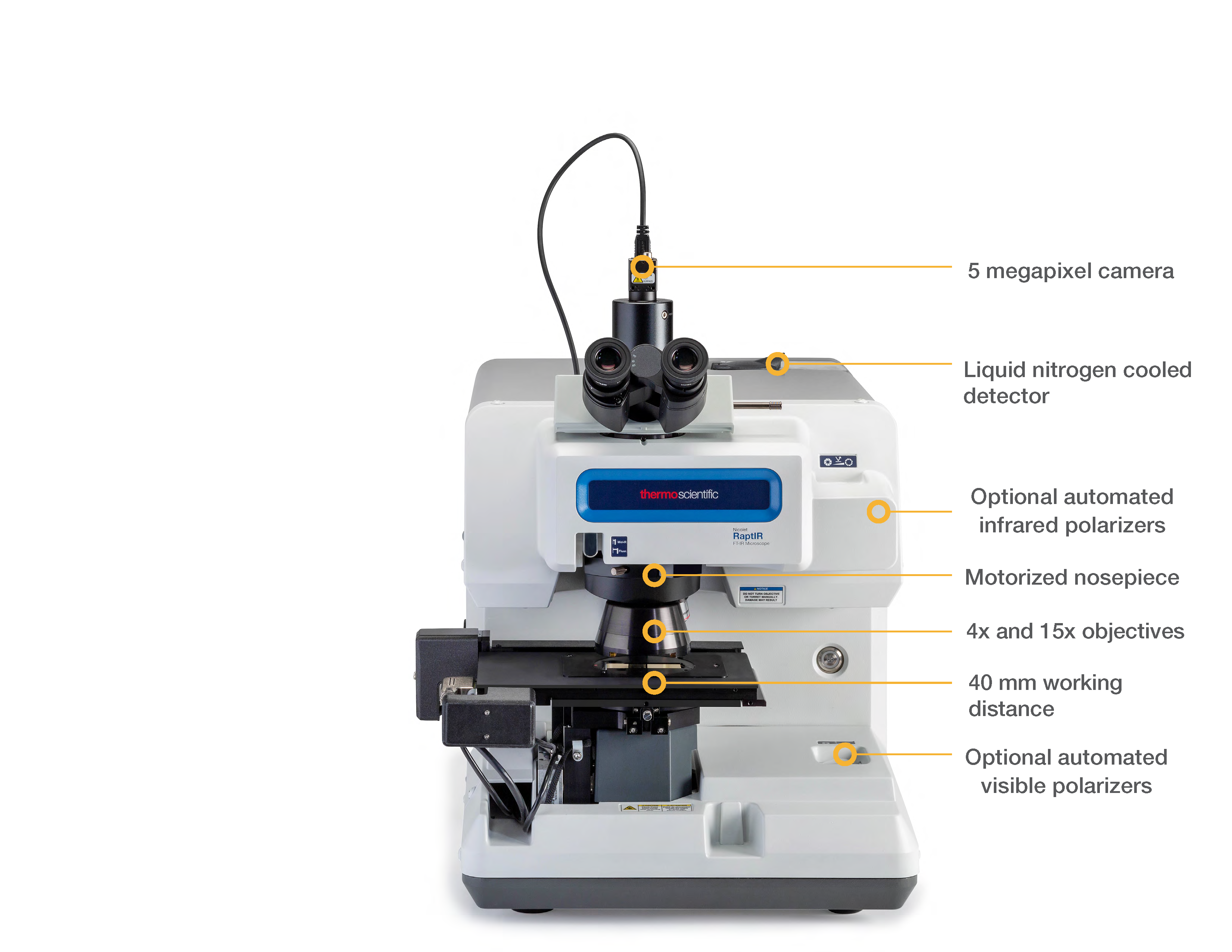

Nicolet RaptIR FTIR Microscope

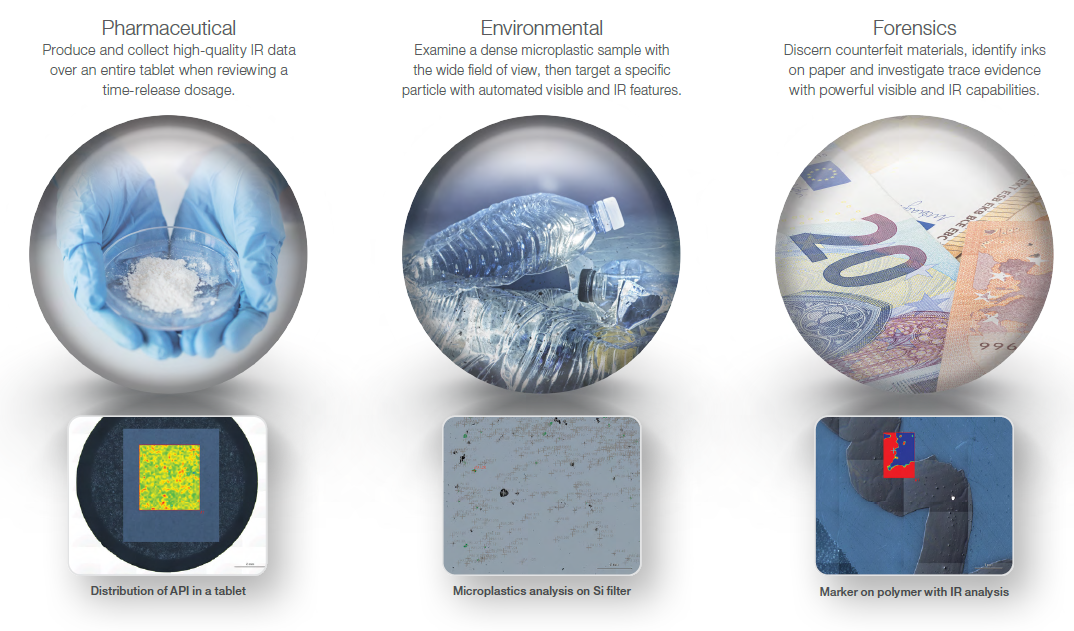

The Thermo Scientific™ Nicolet™ RaptIR™ FTIR Microscope is designed to provide precision and agility with absolute simplicity of operation. Diffraction-limited objectives provide outstanding visual and infrared performance and the new Thermo Scientific™ OMNIC™ Paradigm Software enables users of various skill levels to obtain quality results. Focus on the target, acquire infrared data, and get your results and report faster than ever. This research-grade microscope is not only adaptable for all users but also across industries. The objectives, infrared capability, and clear images are useful in fields of study as diverse as pharmaceutical, environmental, forensics, art restoration, polymers, and materials research.

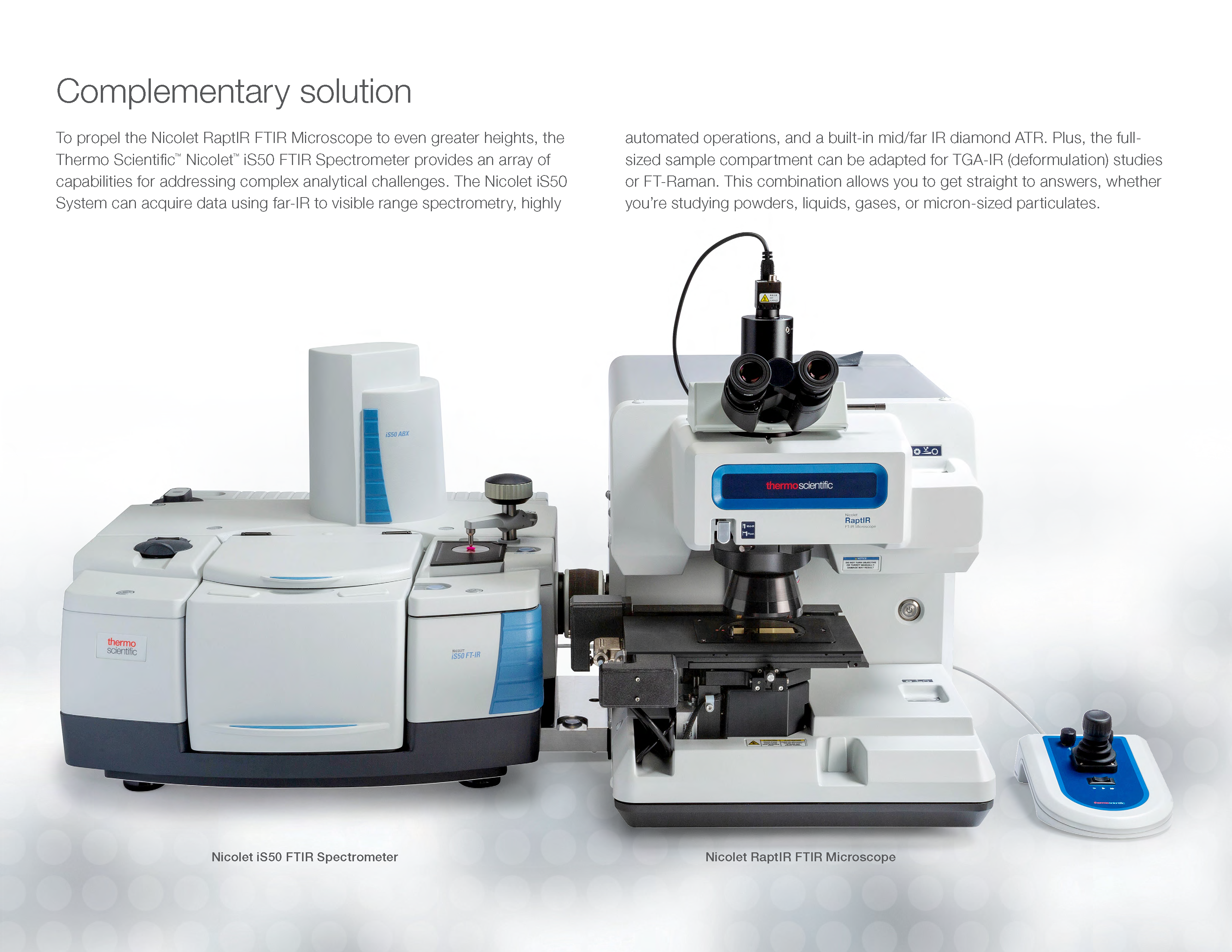

When coupled with the Thermo Scientific™ Nicolet™ iS50 FTIR Spectrometer, the system becomes the ultimate analytical workstation with FT-Raman, TGA-IR, built-in ATR, and multi-range analysis all in one.

Key features of the instrument:

- Measure productivity in microns and minutes

- Open access, heavy-duty stage with a large working distance—allows your lab to explore new applications involving large, heavy samples like artworks or books

- 1-micron resolution via the camera or eyepieces (a new standard in optical quality)—see the smallest details clearly

- Onboard visual assists—find the area of interest quickly

- More than 10 spectra per second at spatial resolutions better than 5 microns—cover a lot of ground, fast, and still get high quality, high-resolution spectra of your sample

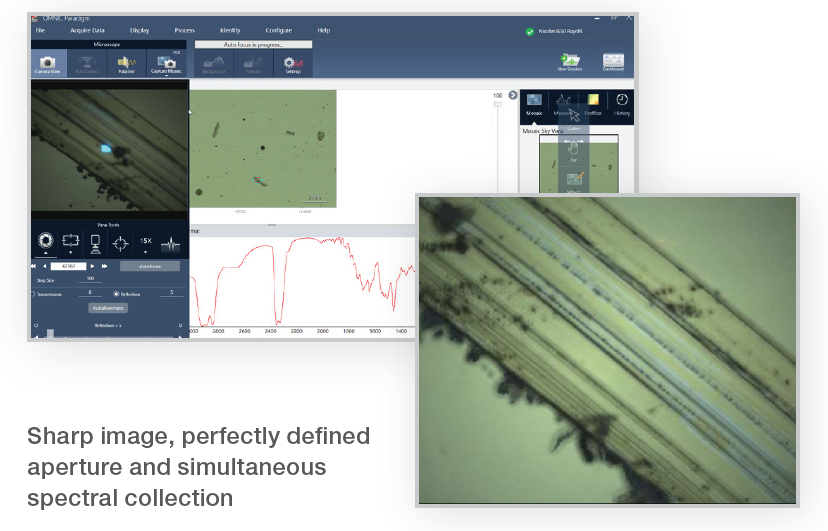

- Clear guidance from intuitive software—extract all the information needed about the target, from point and area

collections to ATR operation and automated analysis of particles on full filters. The software boasts a clean, adaptive user interface (UI), database security, floating tool bar, 64-bit system, and easily generated workflows to automate data collection and analysis sequences. - More powerful together – Combining the leading research Nicolet iS50 FTIR Spectrometer with the newest technology in the Nicolet

RaptIR FTIR Microscope will give you the most versatile FTIR platform possible. In addition, the analysis workflow is fully integrated with the 64-bit OMNIC Paradigm Software, so there are no limits to your data collection and analysis. The entire system is designed to furnish novices with helpful support and experts with the tools they expect.

- Intuitive software-The innovative hardware features of the Nicolet RaptIR FTIR Microscope are complemented by the advantages of the Thermo Scientific™ OMNIC™ Paradigm Desktop Software. It provides users with clear guidance on how to extract information needed from the target. The software boasts a clean, adaptive user interface (UI), database security, floating tool bar, 64-bit system, and easily generated workflows to automate data collection and analysis sequences.

Applicability for microsamples across industries

- Pharmaceuticals (API distributions and purity analysis)

- Polymers and plastics

- Environmental contamination (microplastics)

- Forensics (counterfeiting and trace analysis)

- Art restoration

- Automotive materials

- Contamination analysis in cosmetics and personal care products

- Oil and gas

- Electronics (OLEDs and PCBs)

- Volcanology and mineralogy

- Homeland security

- 3D printing

- Cement and building materials

LAUDA Surface Analyzer LSA100

Ideal for both research & development and quality inspection

- Wide range of drop calculation methods for the contact angle, also including the unique TrueDrop method

-

Accurate pendant drop method with full support for the determination of the critical micelle concentration (CMC)

-

Full support of automatic interfacial tension and CMC measurements

-

Depending on model up to two different dosing systems integrated Optional non-contact dosing systems and numerous other modules and accessories.