List of Industries

ADVANCED SOLUTIONS FOR GLOVE

Our portfolio offers advanced and intuitive analytical instruments to support the design and manufacture of high-quality gloves, which serve as a second skin, protecting us from hazardous conditions while preserving dexterity. Whether for household, manufacturing, or surgical operations, our experienced and professional application support can provide the necessary R&D and analytical solutions to give your business venture the boost it needs.

Incoming Raw Material

Material Identification

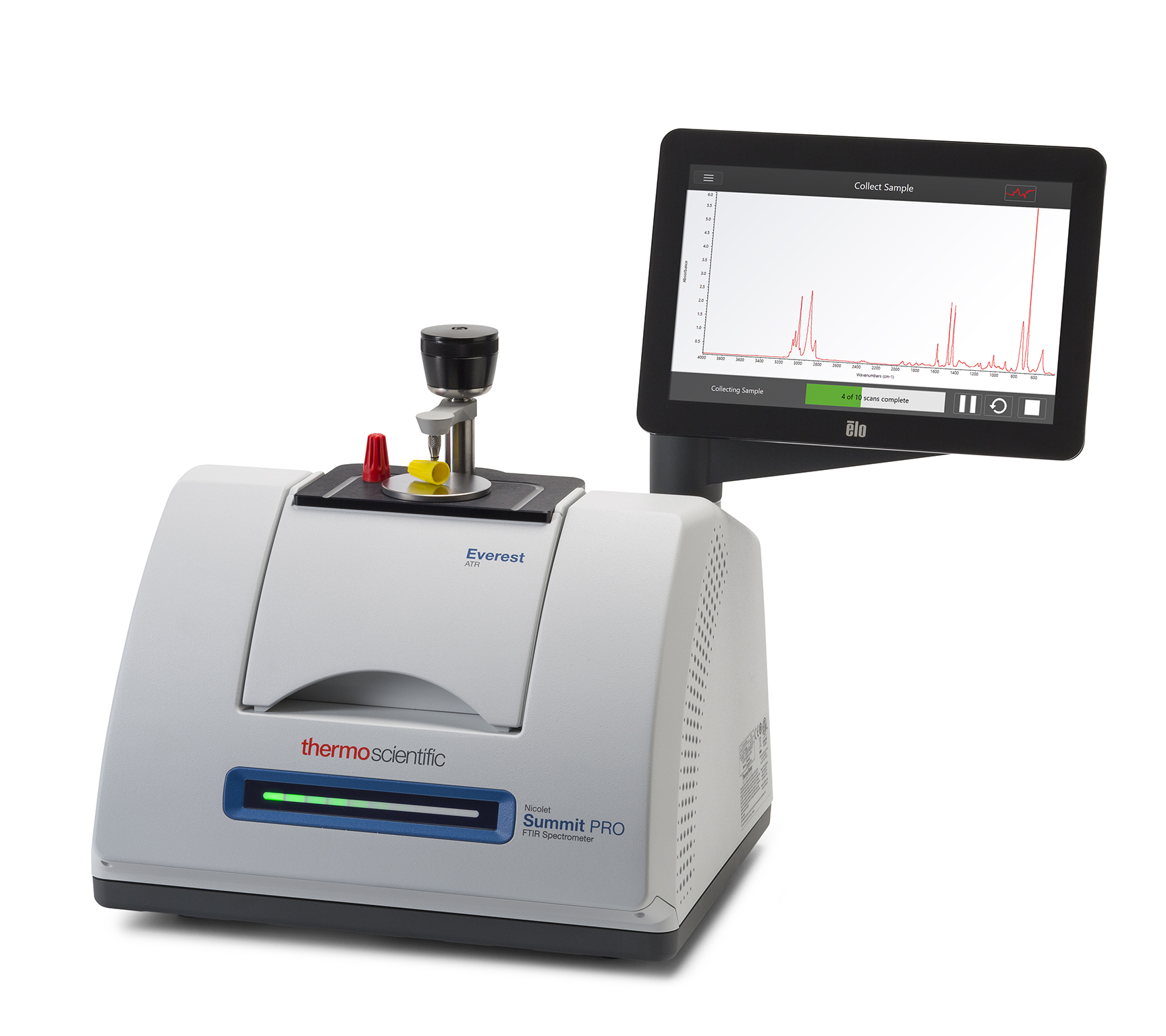

Fourier Transform Infrared Spectrometer (FTIR)

~ It's used to obtain spectral data from organic compounds and polymeric materials. Spectral obtained is used to identify the compound (qualitative analysis), checking of functional group, and measure the change in the composition (quantitative analysis).

Particle Size Analysis For Material Quality Conformance to Certificate of Analysis (COA)

Particle Size Analyzer

~ It's used to measure particle size of raw material using angle and intensity of light scattered by a stream of particles passing through a laser beam. This technique allows continuous measurement of bulk material across a wide size range (10 nm to 5 mm). It can be used to measure the size distribution of emulsion, suspension or powder.

Particle Size Analysis For Material Quality Conformance to Certificate of Analysis (COA)

Fourier Transform Near-Infrared Spectroscopy (FT-NIR)

~ It is an ideal fast quantitation tool for at-line or near-line quality control analysis for organic samples.

Material Profiling

High-Performance Thin Layer Chromatography (HPTLC)

~ It's a separation technique to check on uniformity, purity, and assay check for organic raw material.

R&D Formulation (Compounding Chemicals/Latex- Study for process optimization)

Particle Size Analysis

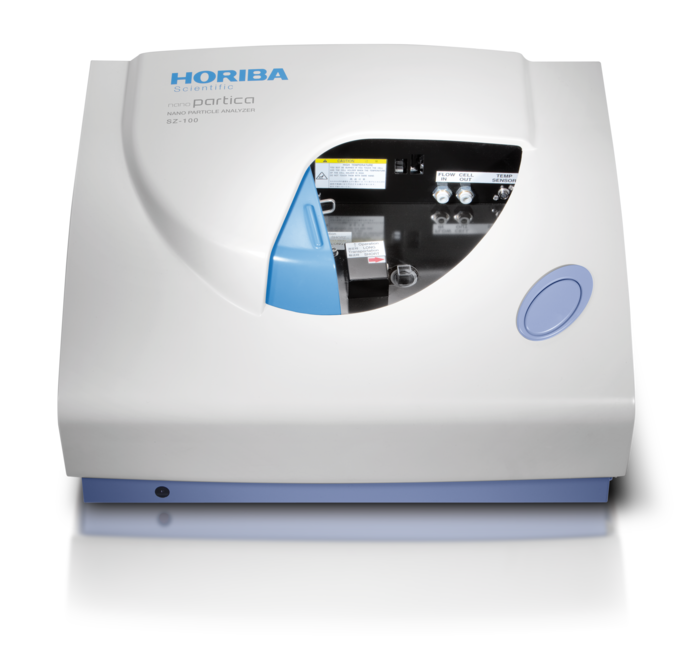

Dynamic Light Scattering

~ It's a nanoparticle size anlysis technique measuring the fluctuations in scattered laser light intensity created by the particles’ Brownian motion. It is widely been used to analyze nano & submicron particle in solution ( 0.3nm to 10 um).

Particle Size Analysis

Laser Diffraction

~ It's a submicron particle size analysis technique measuring the angle and intensity of light scattered by a stream of particles passing through a laser beam. This technique allows continuous measurement of bulk material across a wide size range (10 nm to 5 mm). It can be used to measure the size distribution of emulsion, suspension or powder.

Wettability

Surface Analyzer

~ It's an optical measurement technique to measure the wetting ability of the compounded latex solution and hydrophilicity /hydrophobicity of a substrate by measuring the contact angle. These measurements offer quantitative assessments that can be used to evaluate the coating and cleaning efficiency.

Wettability

Tensiometer

~ It's used to measure surface tension and interfacial tension of the liquid. Typically using du-nuoy ring or wilhelmy plate method and surface tension is calculated using the Young-Laplace equation or other algorithm modals. Surface tension offers quantitative assessments of the coating ability of stock solution before and after compounding.

Zeta Potential For Chemical Dispersion Stability

Dynamic Light Scattering

~ It's a nanoparticle analysis technique measuring the fluctuations in scattered laser light intensity created by the particles’ Brownian motion. It is widely been used to analyze nano & submicron particles in solution ( 0.3nm to 10 um), at the same time it provides zeta potential measurements that indicate the colloidal stability after latex compounding.

Rheology

Rotational Rheometer

~ It's used to determine the flowing properties of a viscous fluid (Non-newtonian liquid). It measures viscosity, thixotropy, shear, and shear strain, from 0.001 to 100 1/s and to quantify the viscoelastic property in oscillation such as loss modulus, and storage modulus.

Thermal Expansion/ Decomposition

Dilatometer

~ It's used to measure dimension changes of solids, melts, powders, and pastes at a programmed temperature change and with negligible sample strain. It is also used to monitor the creep properties of rubber compounds.

Thermal Expansion/ Decomposition

Differential Scanning Calorimeter (DSC)

~ It's used to study a sample heat absorb (endo) and release (exo) profile under controlled temperature program. The data will then be used to calculate the sample heat enthalpy and determine phase transition like Tg, glass transition, melting crystallization and the percent of crystallinity.

Thermal Expansion/ Decomposition

Thermogravimetric Analyzer (TGA)

~ It's used for composition kinetic analysis in the sample by placing the sample under controlled temperature/ or time. This measurement provides information about physical phenomena, such as phase Transitions between the solid, liquid, and gaseous states, thermal decomposition reaction, and oxidation/ reduction.

QA/QC Material Characterisation

Chemical Testing for Crosslink Density/ Curing Study

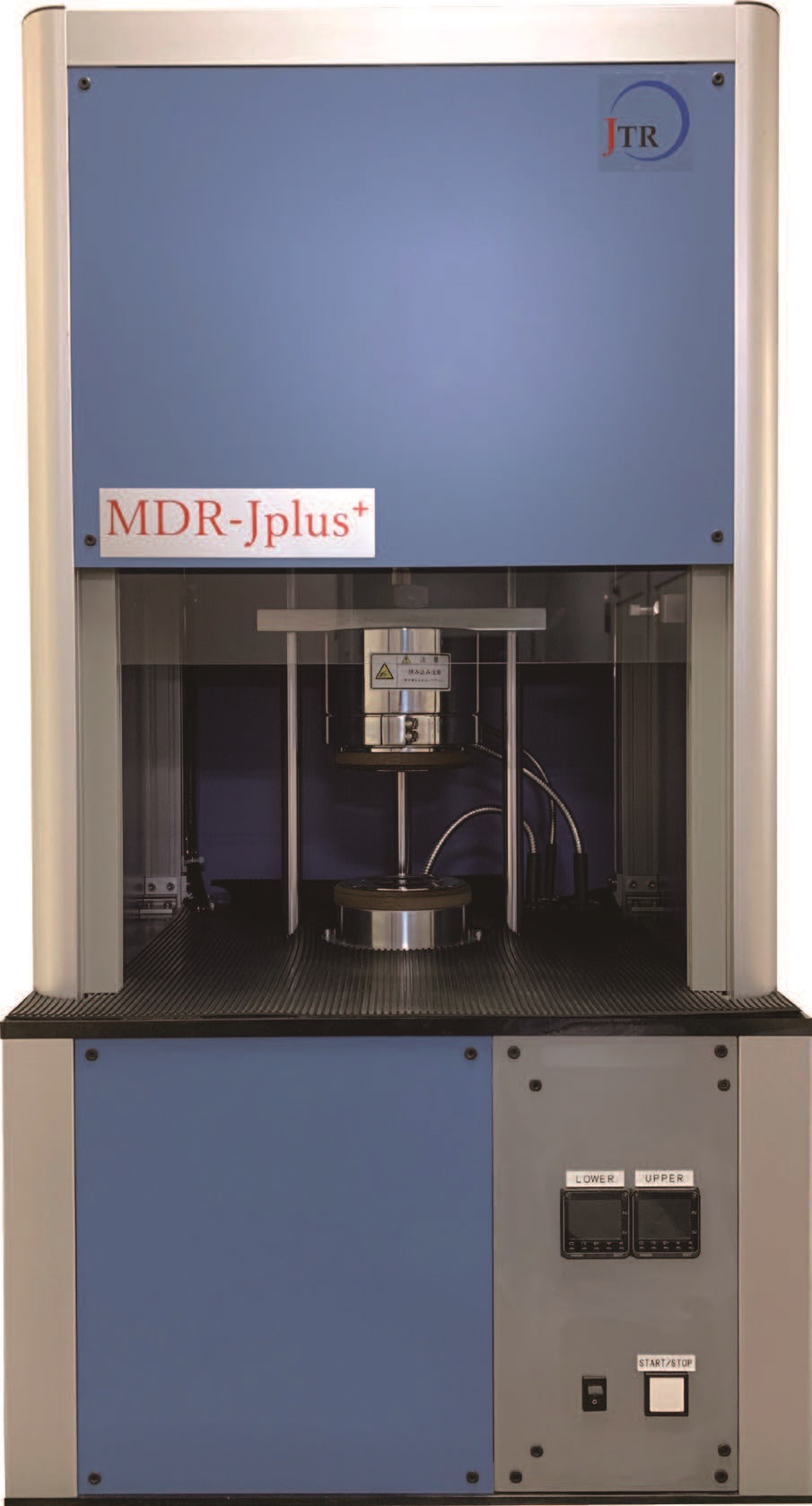

Moving Die Rheometer

~ It's used to measure important vulcanization properties for rubber compounds including viscosity, elasticity, hysteresis loss, and curing rate during the vulcanization process.

Chemical Testing for Crosslink Density/ Curing Study

Temperature Scanning Stress Relaxation Meter (TSSR Meter)

~ It's an anisothermal stress relaxation measurement method (AISR method) to measure the curing density and thermo-mechanical properties of elastomers and polymers.

Failure Analysis/Contamination

FTIR Microscope

~ Coupling FTIR identification ability with a microscope to focus down to ~10um size of organic contamination materials in your samples.

Failure Analysis/Contamination

Raman Microscope

~ Coupling Raman identification ability with a microscope to achieve spatial resolution down to 0.5 um. Raman analysis compliment to FTIR technique as it provides information like chemical structure, phase, and polymorphy, crystallinity, molecular interactions. It's used in the identification of organic, inorganic, or biological materials.

Former Quality

Surface Analyzer

~ It's an optical measurement technique to measure the wetting ability of a liquid and the hydrophilicity /hydrophobicity of the former (surface energy) by measuring the contact angle. These measurements offer quantitative assessments that can be used to evaluate the coating and cleaning efficiency.

Physical Testing Material Strength Study

Universal Testing Machine (UTM)

~ It's used to test the tensile strength, compressive strength, and elongation of materials.

.